The human stool bank set up to facilitate faecal microbiota transplants (FMT) is now developing artificial ‘super stool’ manufacturing capacity to widen access to treatment for conditions such as C. difficile .

Set up by South Australian gastroenterologists Dr Sam Costello and Dr Rob Bryant, BiomeBank is now working in collaboration with bio-engineers at RMIT University, Victoria, to produce synthetic gut microbiome therapies that they hope can replace donor-derived FMT.

The groups have secured $100,000 in funding from the Innovative Manufacturing Cooperative Research Centre (IMCRC) to develop new bioreactor technology from probiotic producers to replicate the complexities of the natural gut microbiota.

BiomeBank CEO Thomas Mitchell says the new manufacturing process will overcome the barrier of having to source material for FMT from the stools of healthy human donors, which is time-consuming, expensive and difficult to scale-up for widespread clinical use.

The new innovation would provide significant advantages to the cost and scale of FMT, and enable more extensive use as therapy for C. difficile infection and IBD.

“This will be a game-changer in the treatment of gut conditions, overcoming the current limitations of donor-derived FMT microbial therapies,” he said.

“We’re thrilled to partner with RMIT on this exciting project, connecting their manufacturing expertise to our company’s unique capabilities in the development of microbiome drug products.

“BiomeBank will use this new manufacturing technology to develop second generation therapies to treat multiple diseases for the broader market.”

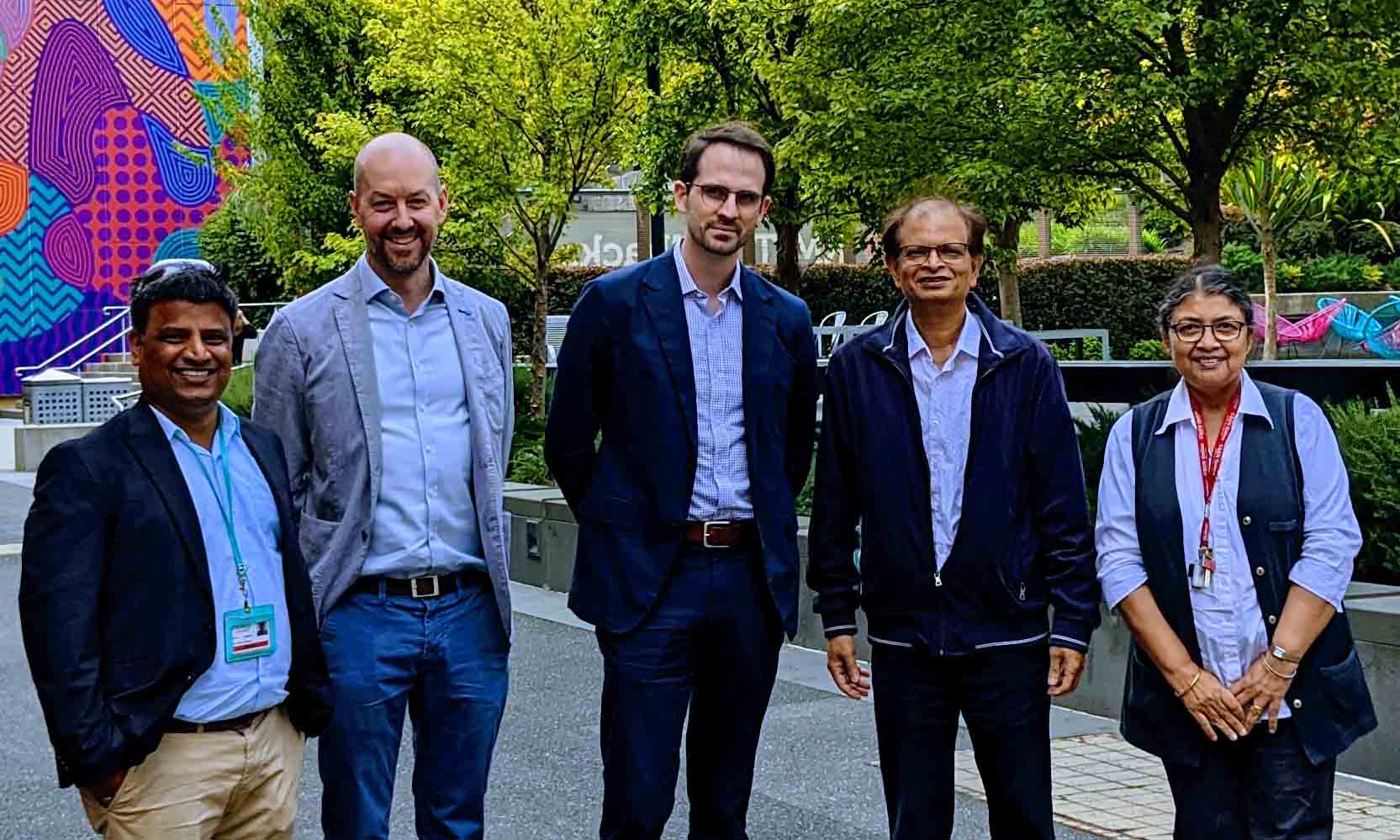

Dr Sam Costello (second left) with Dr Srinivas Mettu (RMIT), Thomas Mitchell (CEO of BiomeBank), Professor Naba Dutta and Professor Namita Choudhury (RMIT).

RMIT School of Engineering researchers say the collaborative project will build on the team’s previous success in developing technology to produce multiple strains of probiotic bacteria in a single bioreactor.

“The new FMT manufacturing technology will support the growth of many beneficial bacteria strains simultaneously,” said Professor Namita Choudhury, Discipline Leader for Chemical Engineering at RMIT.

“While individual probiotic bacteria can be cultivated commercially, we need multiple strains in order to restore the complex microbial diversity of the gut when this is lost due to illness, malnutrition or overuse of antibiotics – and we need to produce these varied strains efficiently and cost-effectively.

“We are excited to collaborate with BiomeBank to deliver innovative biomedical technology into the hands of clinicians to improve the health of millions of people globally who suffer from chronic gut conditions.”

If successful, the bioreactor technology developed as part of the project with BiomeBank will allow Australia to become an international leader in manufacturing industry for medical FMT, according to IMCRC managers.

The project draws on innovations in novel bioreactor development and over 25 years of research in the formulation of hydrogels for biomedical and life science applications by RMIT researchers.

The porous hydrogels are made from sustainable resources and can be precisely designed to support bacteria growth in the bioreactor, mimicking the levels of oxygen and acidity found in the human gut.